Before giving my Leica IIIa a semi-complete CLA, I want to tackle the slow speeds being sluggish problem. Thanks to the Internet, I found a few sites that explained how truly easy it is. I mean, anybody can do this task and perhaps bring their 75-80 year old camera back to it’s former glory.

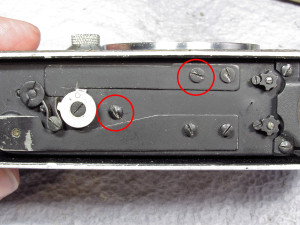

Two screws to get started is all it takes. The hardest part is putting it back in and that just takes some dexterity. This method is possible without a complete removal of the body shell as is needed for the newer IIIb. IIIc, IIIf, IIIg, but if you are planing a shell removal for whatever reason, CLA, investigation of a problem or the like, then by all means, wait until then, it would just be easier to put it back in but taking it out makes no difference.

Continue reading Leica IIIa CLA, Clean the Slow Speed Escapement